Since last weekend we’ve been insanely busy trying to get the goat shed built for our impending doeling arrivals this spring.

It’s interesting how in one’s mind’s eye these projects always seem to go faster than they do in reality, but I think we’ve made some good progress, and the shed is now really starting to take shape.

As with everything on the farm, our terrain confounds any new project.

Everything is ten times more challenging when working on a slope. Even the design on of the shed was complicated by the grade, and moving tools, and lumber, from point A to point B requires more physical effort than if our ground was perfectly level.

On the upside though, we save a fortune on gym memberships here!

Once the foundation was cured enough, the shed building began in earnest last weekend, when two good friends offered to give up their entire Saturday to help us with the initial framing. Each framing stud doesn’t weigh that much, but an entire wall once it’s framed out can get very heavy, so the extra hands were very much appreciated.

The first morning we began by cutting the pressure-treated sill plates, and measuring and drilling out the plates for attachment to the J-bolts on the foundation.

Anywhere the framing came in direct contact with the concrete, we used pressure treated lumber. We minimize our use of any PT on the property, but for this part of the project it was necessary to ensure the long-life of the building. If the sills rot out, the entire building’s structure will be compromised, and trust me, we only intend to build this shed once!

Installing the sill plates was complicated by the changes in foundation elevation, which slowed down construction

Getting the sill plates in place took time, as each plate is bolted to the foundation. As you can see, the rear wall was a bit tricky, with the multiple changes in elevation.

By the end of the day we had the first three walls framed out.

We left the front wall framing for the next day, as framing for the door on that wall was a little more complicated, and we were running out of daylight.

Over the course of the week, into this past weekend, we’ve spent every spare hour we could find during daylight hours finishing up the wall framing and blocking.

Unfortunately, we do have other commitments as well, so we’ve had to squeeze in working on the shed anywhere we can.

Once the four walls were framed and in place, it was time to start framing out the roof. Our local codes not only limit the square footage of the shed, but also restrict the height of the shed at the peak, so the roof pitch is relatively shallow.

We began framing the roof by setting the ridge beam and end rafters in place, finishing up as the sun set

The roof framing is fairly standard, with a center ridge beam, and bird’s beaks along the rear top plate, and notches cut for the lookout rafters.

The tail rafters appear longer in the back of the shed at the moment, as the front roof rafters will be joined to the rafters on the front deck roof, so things look a little lopsided at the moment.

If the rain stops today, we hope to get the footings for the deck in place by mid-week so we can finish the roof, and get it sheathed.

The deck roof height has to be set before the fencing crew can begin, as the enclosure will be covered, and needs to meet the edge of the deck roof.

Taking advantage of our dry weather last week, I spent most of a day preparing the siding for installation. This required staining a LOT of sheets of T1-11.

When we inquired about hiring a shed-building company to install a shed for us, the sheds would have been constructed using cheaper grade, pre-primed, T1-11 panels, which necessitates using paint as the final finish. Not really the look we were striving for. As we opted to build our own custom shed from scratch though, we decided to use raw T1-11 so we could stain it, rather than paint it. This will not only integrate the shed better into the woodland surroundings, but also ties the shed better to the other structures we’ve already installed on the property, from the greenhouse, to the raised beds, chicken arks, and barrel planters.

With the siding stained, and dry, this weekend we focused on getting it installed. Of course, very little of the siding installation was straightforward, as almost every sheet required some degree of creative cutting, either to accommodate the foundation elevation changes, or the cutouts for windows and doors.

I’d forgotten just how heavy a single sheet of T1-11 is, so wrangling that into place with just the two of us didn’t go quite as fast as we hoped, but we’re almost there.

During the week this week I’ll start construction of the ‘windows’.

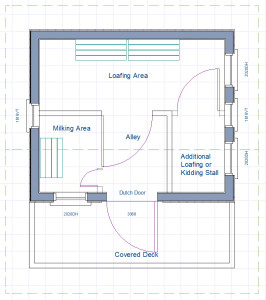

We’re not using traditional windows in this barn, but instead constructing vented openings with shutters that can be opened and closed to control airflow within the barn.

Predators have been known to defeat conventional windows, and they’re often considered to be a weak point in construction when designing a predator-proof barn. There will be a total of three 2-foot x 2-foot windows.

These ‘windows’, however, will only be on the two walls that will ultimately be inside the covered enclosure. We’ll be using rustic-looking expanded metal panels in the window openings, as it’s much more durable than hardware cloth.

The shuttered windows, in addition to the roof’s ridge vent, the wall vents, and the dutch door, will help to maintain good air quality, and decrease humidity within the barn.

Although things aren’t going quite as fast as we hoped, in two weeks we have gone from a patch of weeds and dirt, to a structure that’s starting to look like a real shed.

It’s quite a balancing act between the garden and goats this week, but hopefully by the end of this next weekend the shed project will be mostly wrapped up so we can get back to transplanting for spring before the goats arrive.

So, as shed building is temporarily halted due to rain, I’m off to the greenhouse to get some seed starting done. I need get our tomato seeds sown so we can get our spring tomato-grafting project underway!

It’s looking really good! I really like the style of it. I bet you’re busy right now, it’s getting to be that time of year.

Thanks! Between wrapping up the barn, and thinking about spring prep and planting, I think I need to figure out how to add 12 extra hours to the day! Thankfully, the clocks will change soon, and at least grant an extra hour of daylight at the end of the day 😉

Looks like so much fun!

Those goats will have a fantastic view — wow!

It is fun…well, except for the Ibuprofen part 😛

You are doing a fantastic job and that shed will last a long time. I can sure empathize with the hard work. I can’t remember if I blogged about our shed building but it was the tiredest I’ve ever been in my life. You’re doing great the two of you!

I actually woke up in the middle of the night one night, and went to roll over, but my arms literally felt like lead! I agree, shed-building can be exhausting! We’ll be glad when it’s done, both because it will be done, but also because then we can enjoy it 😉

Clare,

This looks pretty good, almost finished! Work has been slow for me. A good customer of mine wants me to build a play house for her 7 yo, so I have a small building to make also. Have fun with the goats.

As children have a habit of growing, if your client is amenable, I’d be tempted to see if the play structure might be able to be designed such that it could double as small garden storage shed once her son has outgrown it. We’ve designed this structure so that whoever might own this property after us could simply use it as a standard 10×12 shed, sans goats, if they choose too.

What lucky goats!! The closest I come to goats here is watching middle schoolers chew gum.

I’m lucky too…as I’m sure I’ll be spending quite a lot of time in this shed once it’s finished 😉

Clare you sure don’t need gym membership and I must say that you’ve chosen a beautiful location for the barn. It looks like those large trees will also give it a bit of protection.

They’ll definitely be well protected from the winds here, and they should get some nice shady areas in the heat of the day too. It’s been an awkward place to build a shed, but as it’s on a slope, at least we know it will drain when it rains!

I am *very* impressed! You have done a lot of work, and it looks like it’s perfect! Great planning, too. You will have some very happy goats!

It has been a lot of work, on a pretty tight schedule, I keep looking ahead knowing that the sore muscles and sheer physical exhaustion will be worth it in the end 😛

Clare I am exhausted thinking about all the work you are doing building the shed and then all the work when you aren’t building the shed…I guess I am more suited to a desk job…I love the shed and all the thought that has gone into its construction…the goats are very lucky you chose them!

There hasn’t been much of anything going on that wasn’t shed-related the last two weeks. My vacuum cleaner thinks I’ve left home, and the greenhouse is convinced it’s been abandoned 😉 Things should get back to ‘normal’…whatever that is, soon!

It’s looking good. Love the setting by those big trees!

I love the views here, I hope the goats will too! 😉

Goats now?!?! I’m impressed. I’ve missed the goings-on on your farm. And this is quite the building project to keep them safe. Very impressive and very fun to read about.

oh and that was only my 2nd time on Angel Island in 17years. And I’ve never sailed around it. I think it often takes us longer to see things in our own backyard than as tourists somewhere else.

Can’t wait to see the goats.

We’re gluttons for punishment 😛 There’s no question, small as we are, that we’re a farm now!

Wow, amazing! It makes me tired just to read about it. Should be very interesting to have goats. One day I’d love to visit – will you have farm days?

Probably not open to the public ‘Farm Days’ per se (liability potential and what-not make public group events here unlikely), but we will be inviting our friends to the farm soon, as soon as this place stops looking like a construction zone 😉

Okay, okay, exactly who is ‘we’???!!! You are beginning to appear like a one woman superman. Holy cow thats a lot of work.

Ah, ‘we’ would be myself and my partner in crime, Mr. Curbstone. No capes and tights, just the two of us. 🙂

You two are so incredibly handy, it’s amazing.

Thanks Carolyn, sometimes I think we even surprise ourselves…I just wish I was 20 years younger 😉

Your goats are already spoiled! Having said that I realize how important it is to build something correctly at the start, and you are doing such a great job. We have a sloped backyard, and I know exactly how many challenges you face whenever there is a project on the list. We seem to always need so much more time and materials -put in so much more thought- than if we did not have the slope.

Aren’t they though? That’s ok, the goats deserve it. The one thing we didn’t think about when we purchased this property was how much more challenging the slopes are to work on. I mean, we thought about it a little bit, but didn’t quite realize just how much more work it would be. That’s ok though, it will keep us young…well, somewhat 😛

You are doing a terrific job! Your goats will be well protected and will love their new home. I am always impressed by the quality of work you do, no matter what the project is. Perhaps by now you are close to finishing. I look forward to seeing the shed when it is completed, and even more I look forward to meeting your new goats.

We are…finally…close to finishing. Most of the roof is done, the windows and shutters are finished, and today I’m wrapping up the shed dutch doors. We’re finally seeing the light at the end of the tunnel 🙂