Making cheese at home used to be commonplace. Today the majority of us simply buy cheese, ready to eat, from our local markets, as the majority of today’s cheese is mass produced in factories, especially in the United States and Europe.

When we first started to dip our toes into the world of cheesemaking, we looked first into the history of the craft.

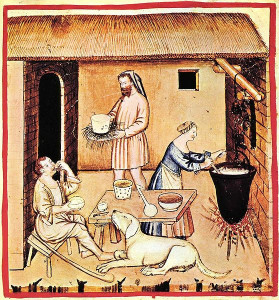

This image depicts cheese making in 14th Century Italy. Note the perforated cheese strainer/mold on the upper left corner of the table. (Image: Public Domain)

The origins of cheesemaking are unclear, but clearly predate recorded human history. Recently, archaeological evidence of dairying in the grasslands of the Sahara, suggests that milk was an important diet staple as early as 8000 BC. [1] It’s not unreasonable to expect that some of that milk may have been used to make at least some simple types of cheese.

Sherds of perforated pottery, presumed to have been used in early cheesemaking for draining whey, have been found in areas of France, Denmark, and Germany, dating at least to the late Bronze Age. [2]

Regardless of its origins, cheesemaking was obviously a practical method for dairying cultures to extend the shelf-life of milk. By producing cheese, milk that otherwise would have spoiled could be stored for extended periods of time, transported, and even traded as a commodity.

The earliest cheeses made were likely simple coagulated soft cheeses, similar to a cottage cheese, or Chèvre. Cheese curds are drained and shaped using strainers, or molds, known as Faisselles.

Traditionally, such strainers, or molds, were often crafted of wood, tin, or pottery. However, vintage molds are difficult to find in any quantity today, as they have been replaced by molds made of more modern materials since the early 20th Century.

Of the traditional molds, the ceramic molds are perhaps the most practical as the glazes make the molds easier to clean than wood, and occasionally a few of these molds can still be found for sale.

Modern commercial molds are typically stainless steel, however, most home cheese making equipment today is made of plastic. Everything is plastic, including cheese ripening boxes, and draining mats, and most especially the cheese molds themselves.

There are practical reasons for using plastic molds. They’re easy to clean, lightweight, and of course, they’re very affordable. If you’re just going to dabble in cheesemaking, plastic molds are fine, but I can’t help but feel that it takes some of the charm out of the process of crafting one’s own cheese.

Even though they’re cheap to manufacture, I do wonder what the total cost is of a plastic mass-produced mold, between manufacturing, and transportation. Most seem to be made in Asia, or Europe, and I have yet to find any manufactured here in the United States.

The disadvantage of plastic molds is they can become brittle with age, and repeated washing, making them prone to cracking or splitting over time.

Ultimately though, the plastic molds, to my eye at least, are completely bereft of any charm or character, and quite honestly the couple of plastic molds I do own are hidden in the back of the kitchen cabinets, far out of view.

As cheesemaking, like bread making here, is becoming a lifestyle choice on the farm, we had an idea!

We decided that we don’t have to buy plastic molds from thousands of miles away, made by someone we’ve never met, just so we can drain and mold our cheeses. The trouble was, we couldn’t find much in the way of alternatives locally.

It’s not essential to use a mold for soft cheeses. This particular Chèvre was simply shaped in muslin, and hung to drain.

As you can see from the plastic molds shown above, cheese molds are relatively simple in their design, so in the spirit of shopping locally I decided to contact a friend who enjoys dabbling in pottery in his spare time.

After discussing the practicality and use of the molds, and pointing to a few historic designs, versus the modern plastic characterless choices on the market, I asked if making something as mundane as a ceramic cheese mold would be something he’d be willing to take a stab at. To my delight, he agreed to give it a try!

We forwarded some photographs we’d pinned to Pinterest of some traditional French Chèvre and Roquefort molds as inspiration.

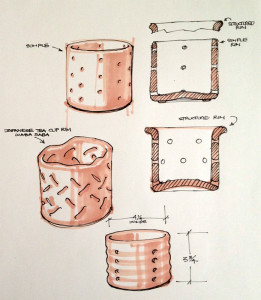

Before we knew it there were prototype sketches waiting for us in our inbox!

The advantage of commissioning custom crafted ceramic cheese molds, providing they’re food safe, is that they can be almost anything you want shape-wise. The most important part of the design is that there are a sufficient number of drain holes for the style of cheese being produced, that are regularly spaced. The holes permit the whey to drain, providing the holes are appropriately sized, and prevent loss of curds.

We loved the Japanese tea cup rim idea in the conception sketches, but sometimes it’s necessary to invert the molds to ensure the whey drains out completely, and that style of rim would be less stable when inverted. After discussing the practicality of the overall design, we arrived at a classic, simple design for our unique, handcrafted, one of a kind cheese molds.

It was so much fun getting occasional updates about their progress as they were being made.

Soon the first prototype was ready, with a beautiful rolled edge to the rim, and plenty of evenly spaced holes to ensure even draining of the whey from the curds.

From paper, to potter’s wheel…the first of the molds, made of Black Mountain clay, takes shape (Image © 2012 – Loren Stirling)

Once the remaining molds were made, a food-safe glaze was chosen, and applied to the molds.

Of course, as is the case in all pottery-craft, you never really know exactly how the finished product will look until the final firing of the glaze.

We think these molds turned out beautifully, don’t you agree?

Each vessel has its own character, with slight variations in size, or the character of the glaze, just as you’d expect from a truly handcrafted piece. Far more interesting to look at than a generic plastic mold.

Best of all, turning the mold upside down, instead of being stamped with “Made in …” on the bottom, each of these molds bears the artist’s name instead.

We can’t wait to use these traditional-style molds during our future cheesemaking endeavors. Each time we use them we’ll be reminded that the tools and equipment used in artisan cheesemaking have changed very little over millenia. Thank you so much for working on this project with us, Loren!

————————-

[1] Dunne, Julie et al. First Dairying in Green Saharan Africa in the Fifth Millennium BC. Nature: International Weekly Journal of Science. June 2012 486:390-394.

[2] Nash, Lyman. Cheese: Its Delights and Differences in The Rotarian. Feb 1969.

The molds turned out beautifully! He may have a new business thanks to you 🙂

There’s been such a resurgence in home cheesemaking in recent years, you might be right! I think anyone that makes cheese on a semi-regular basis would love these 🙂

and us non-cheesemakers could use them for storage just because they look so appealing. (Bit wary of plastic leaching into the cheese, but then we buy cheese packed in plastic :~((

Mr. CV thought that a larger mold, with a lid, would make a great cellar for storing garlic bulbs in, and I have to agree!

I love the molds! How wonderful to know someone with the talent to help bring your idea to fruition.

I’m relieved I know someone with the talent to do this. I certainly couldn’t pull it off. My early attempts at pottery were…well…amusing. Yes, that’s it…amusing 😛

Beautiful and functional! How fun to make your own cheese! My mother-in-law makes her own paneer sometimes (mmmm..) I’ll bet your homemade cheese is delicious. Enjoy using your gorgeous new molds!

I actually haven’t made Paneer yet, although I keep meaning to. Homemade cheese is truly delicious, and fun to make too! It satiates both the art and science halves of my brain 😉

Thanks for the little history lesson on cheese and molds Clare. You are your own person of course ;-), but because I always learn something, I think of you as the small sustainable farm woman version of Alton Brown. Interesting backstory and information are why I look forward to your posts! Oh, and the pots Mr Stirling made are beautiful!

Sincerely,

Mrs Stirling

I love Alton Brown. I have the sort of brain that’s never satisfied with just knowing that something is…I want to know WHY it is. Or how, who, when, where. Yes, I was one of those annoying kids that always asked too many questions, can you tell?

I agree, Mr. Stirling did an excellent job. I love that this project keeps both the art of cheesemaking, AND pottery, alive and well 😀

How interesting! I am impressed with the final product. You may have inspired a new cottage industry! Depending on their size, I think the molds would make great candle holders for those who don’t make cheese.

Like minds Deb! I said the same thing when I saw them. Because of the holes, they’d need a hurricane-type insert though, so the wax didn’t run out, but I bet they’d look lovely illuminated from within!

You never cease to amaze me Clare with all the new projects you take on. Those cheese molds are so bespoke and would look lovely on a kitchen shelf. I’m not so sure if cheese making is as popular over here in the UK but considering the news we had last week on how much salt is in supermarket cheeses a few people might be thinking of making their own instead.

I read that article on BBC News about sodium levels in British commercially produced cheeses. You can’t eliminate salt from cheese, as it’s a necessary part of cheese production, but some cheeses could certainly have their salt levels reduced without upsetting the flavor or quality of the cheese. That is the advantage of making your own.

I’m not sure that a lot of people here are making their own, but home cheesemaking is definitely making a comeback in this area at least!

Dear Clare, this is so wonderful it brought tears to my eyes! Such a fine endeavor and beautiful molds. You are an inspiration to us all.

xoxoxo

F

Thank you Frances. I was thrilled with how they turned out, and so happy that we could see our crazy idea all the way through to a finished product 🙂

I see a future ad in ‘Culture’ magazine….or in the Williams Sonoma catalogue!

Ooooh…I love ‘Culture’ magazine. Sometime I want to reach into a page and pull out the beautiful cheeses they write about. Mmmmm 😛

Congratulations! What a great idea, and I love the results! My concern would have been chemicals leaking from the plastic molds into the cheese after repeated (and repeated) use and the ceramic will probably stand the test of time much better.

You’re right, there’s definitely no BPA in these molds! 😉 I expect they’ll wear and age beautifully too.

Now that we hav learned about the molds do we get cheese making 101 or did I miss a post on that. I would love for you to show step-by-step how to make the absolute easiest cheese.

I did post a recipe, with simple step-by-step instructions for making an easy goat’s milk Chèvre here. Of course, there are few obligatory goat photos, but scroll down, and the recipe, with photos is in the last half of the post. I do plan on posting some more cheese posts in the near future though. Making cheese is a great rainy-day project! 🙂

I cannot wait to follow this blog on cheesemaking! Love it so far – thanks for the info and look forward to it!

Clare I have watched cheesemaking on TV…I believe it was Italy and it was fascinating…we do eat too much factory made cheese…i would love to sample more homemade cheeses…how great to commission these molds…can’t wait to see your cheesemaking!

Clare, you never fail to amaze me at the amount of projects you take on! Looking forward to hearing more about cheese making as I have no knowledge about this process at all. I understand your interest in a classic and long wearing mold though. I must admit I have collected several antique wooden buttermolds for no reason other than their charm and beauty.

The molds are beautiful, Clare. Cheese making is an art and it will be fun to see what you do with this. Loved the history too.